About us

KMH-Kammann Metallbau.

Long name, briefly explained.

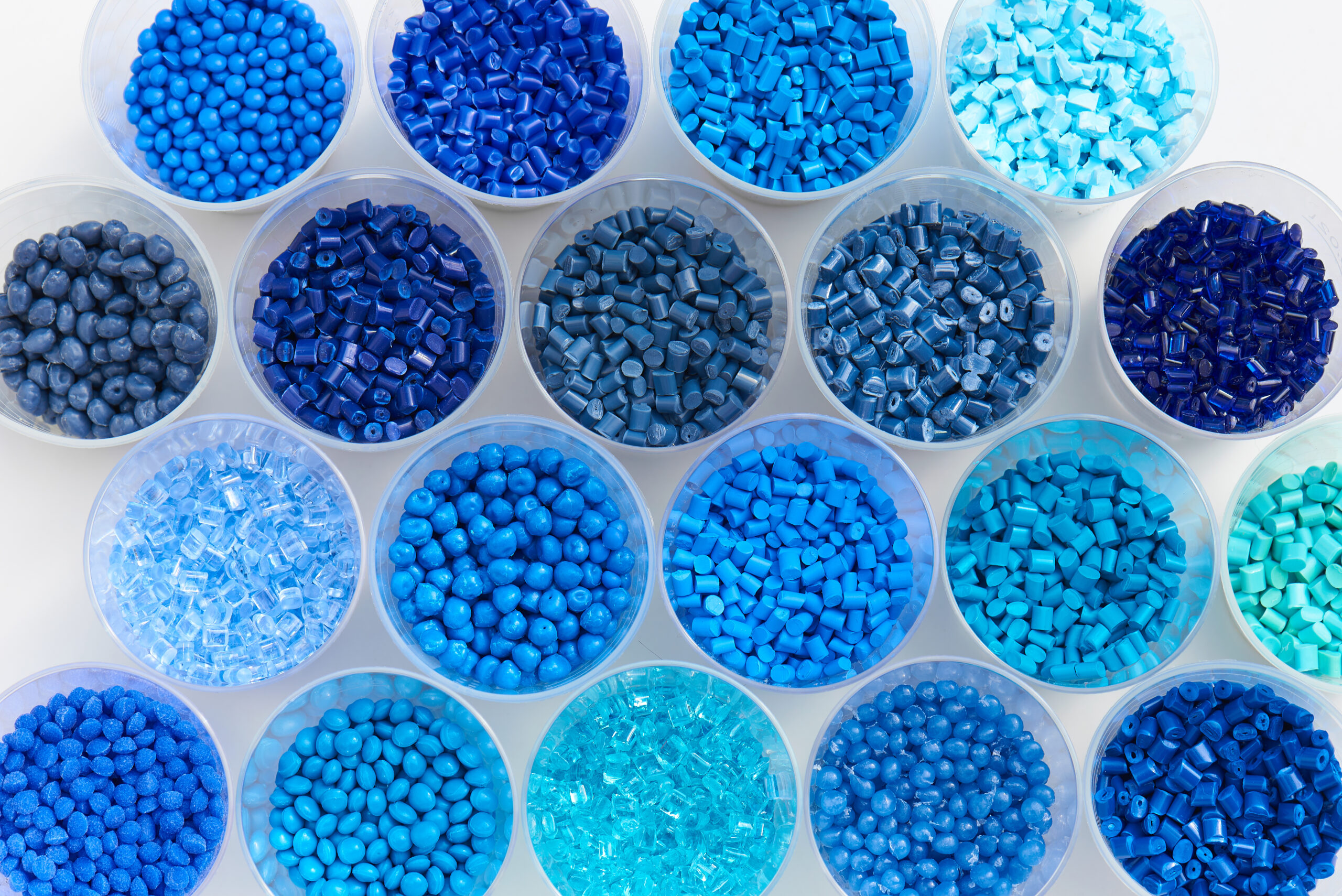

KMH is one of the leading manufacturers in Europe of clamping rings or flange-connected pipes, components and systems made of steel and stainless steel for aspiration and bulk materials of all kinds. Phew, done!

We offer an extensive range of pipes, moulded parts and distribution systems in “modular system”. Furthermore, we are also the number one in special construction. Our specialities are individual pipe systems and custom-made special designs of all kinds, in order to be able to respond quickly and flexibly to your individual requirements.

- Everything is completely made in-house – Made in Germany.

- We are: fast, innovative and competent in implementation.

- for over 35 years. Worldwide.

- Whether standard range, series or custom-made – we are there for our sustomers!

KMH philosophy

We want to convince with actions!

We have over 35 years of experience in pipe system production. Thereby, we concentrate on the essentials – that is to say, the modular products that you need from one day to the next. Delivery ex-works. Full speed. We have (almost) the whole range in stock for you. All you have to do is decide on the surface (powder-coated, pickled, blasted, galvanised, …).

We have Power. Individual production is part of our KMH philosophy: We build even the most complicated special products within the shortest time after technical clarification. Custom-made special products of all kinds are our speciality.

We are flexible

We are the No. 1 in special construction!

Our goal

Actively shaping change

With our portfolio of outstanding customers and individual products behind us, we are now taking the next step towards the future, in order to become even better – for you! The past few years have already been marked by major changes for our production: new production areas, new production structures and technologies.

But we don’t want to stop and linger here. Rather, as part of our continuous pursuit of improvement, we constantly question our actions. Be it new technologies, organisational structures and processes, or even employee qualifications, we are constantly striving to use new technologies to increase our production speed and improve quality for you. We align our structures and processes with value creation, in order to provide you with an efficiently manufactured product. We are constantly developing the qualifications of our employees, in order to create the basic conditions to meet your level of individuality and quality requirements, or even to be ahead of them.

With all these changes and developments, we always focus on one thing: to be a better provider of innovative and individual products for you, our customers.

KMH in Figures

5.000+

standard products

24

international agencies

35+

years of experience

230+

employees

Certified quality work

Best quality with sustainable aspiration

We want to offer our customers the best-possible quality and best-possible service.

We are committed to acting as sustainably as possible. That’s why we work with the following standards:

Our history

History

- 2024

Commissioning of a 3D laser system for two- and three-dimensional cutting and welding, commissioning of a fully automatic pipe production line with a 5 KW laser - 2023

Commissioning of a fibre laser cutting system, introduction of laser manual welding in special construction - 2022

Conversion to a standard “perfectly blasted stainless steel surface”, use of welding robots in series production;

Commissioning of a state-of-the-art projection welding system for the production of clamping rings - 2021

New type of rotary head distributor with patented docking system - 2018

Catalogue appears in a new design - 2017

Hall expansion by additional 5,000 sqm to a total of 15,000 sqm - 2012

Over 120 employees, representatives in Germany and in 45 countries – and the new catalogue - 2011

Anniversary: 25 years KMH

Expansion of the explosion pressure shock resistance to 10 bar up to DN 250mm - 2009

Relocation of the entire company within Bassum to 10,000sqm. Introduction of a conductive paint that eliminates the need for the usual grounding using grounding lugs and cables or grounding clips;

Expansion of the explosion pressure shock resistance also for 1-1.5 mm pipe parts with clamping ring connection - 2008

Development and market launch of KMH grounding lugs

- 2006

FM-certified supplier of E-CTFE/Halar-coated pipes and moulded parts (chemical-resistant) for the clean room, semi-conductor and solar industries; Approval can only be obtained through testing procedures in the USA - 2004

Certified expansion of the explosion pressure shock resistance - 2002

Start of production of free-flow valves - 2000

Market launch of a pressure-tight 2-way valve - 1999

KMH moves to Bassum, on an area of 6,500 sqm, the (now) 80 employees have enough space - 1996

KMH continues to grow: From 500 sqm to 4,500 sqm with 45 employees - 1995

KMH now offers its customers complete pipeline installations including insulations - 1988

KMH sets (catalogue) standards: “The blue” with the world-wide clamping ring - 1988

New development of a rotating and pivoting (and therefore particularly easy to install) KMH clamping ring;

Today, this clamping ring is considered to be the standard on the market - 1987

Development of the first special machine for in-house production - 1986

Founding of the company by Günter and Elke Kammann in Harpstedt