Allow me to introduce myself – Trumpf:

I’m the new one.

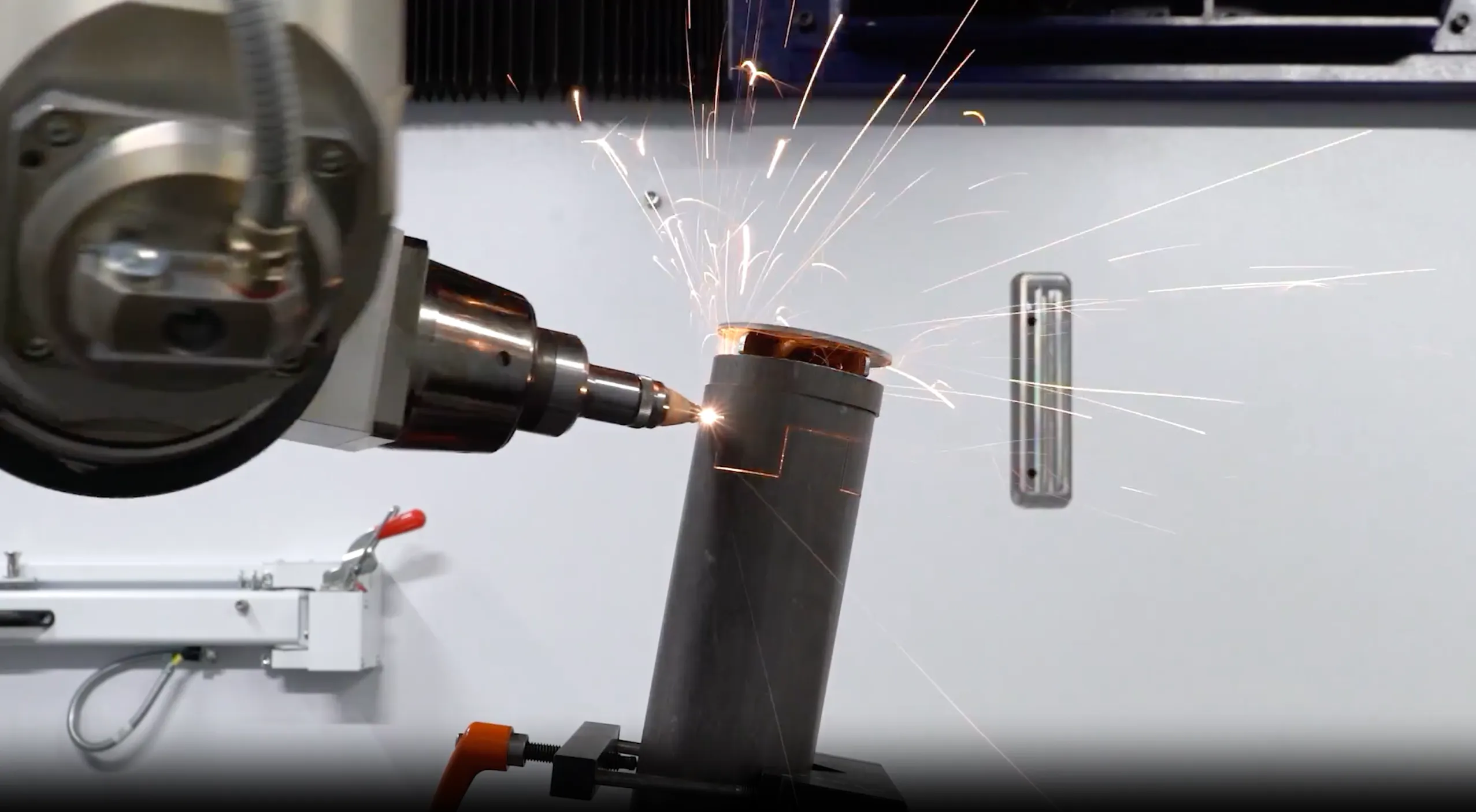

- Laser cutting with 6 axes,

- Laser welding with 6 axes,

- With 0 compromises.

With our new 3D laser, we can now cut and weld angles between 15 and 95 degrees for tubular and shaped parts—on request. And since no rigid tools are involved, there are no tool-related compromises either. For you, this means: maximum flexibility, minimal variations in material thickness, outstanding precision and quality, and significantly less spatter inside and out.

By the way, this new highlight in forming and joining technology is a »trump card« for us in more ways than one. After all, what better way to shape the industry of tomorrow than with an experienced market and technology leader?

More flexible, more efficient, and with lower CO₂ emissions?

Kammann. Can!

Your ideal dimensions? Your choice!

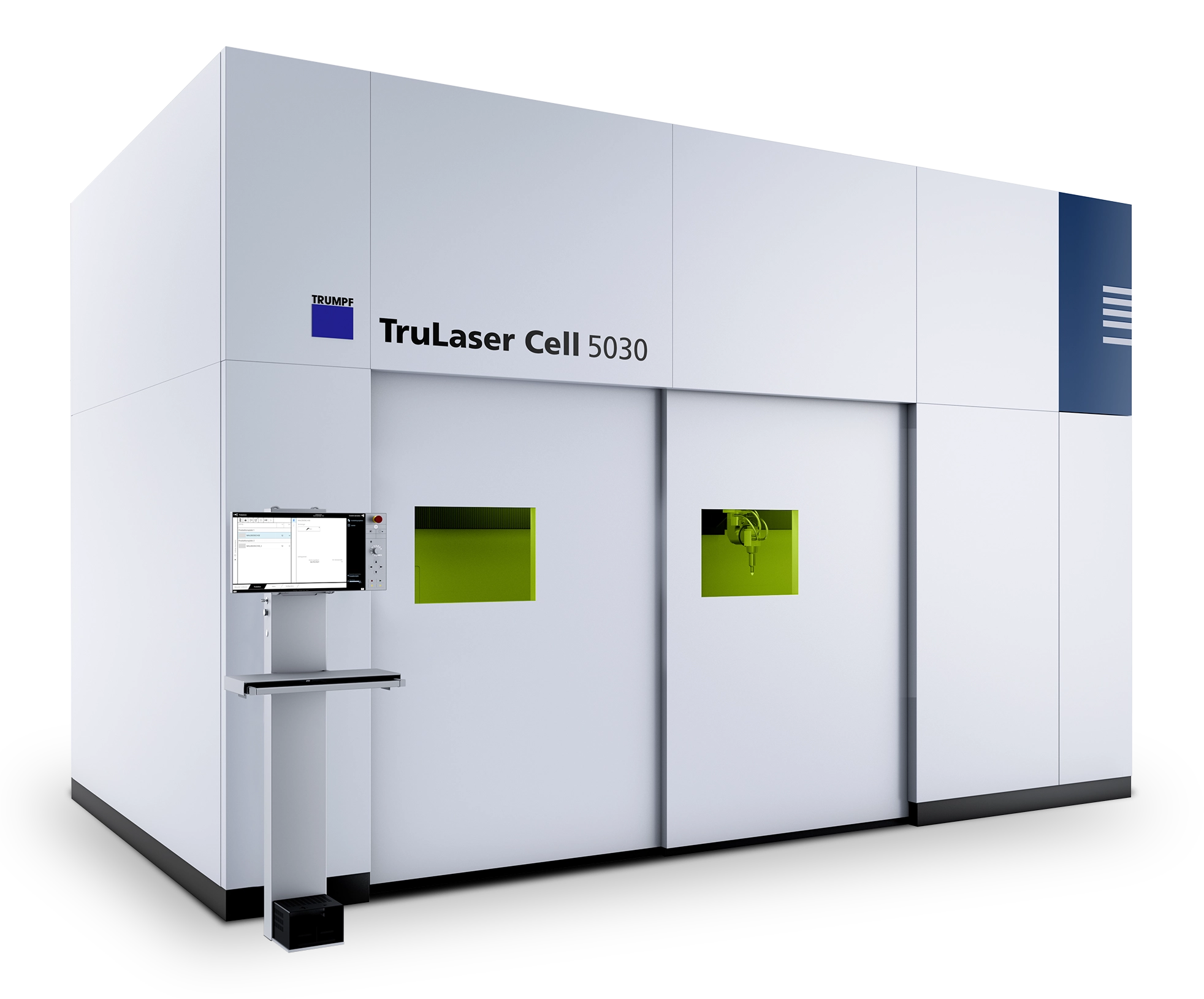

Entering New Dimensions

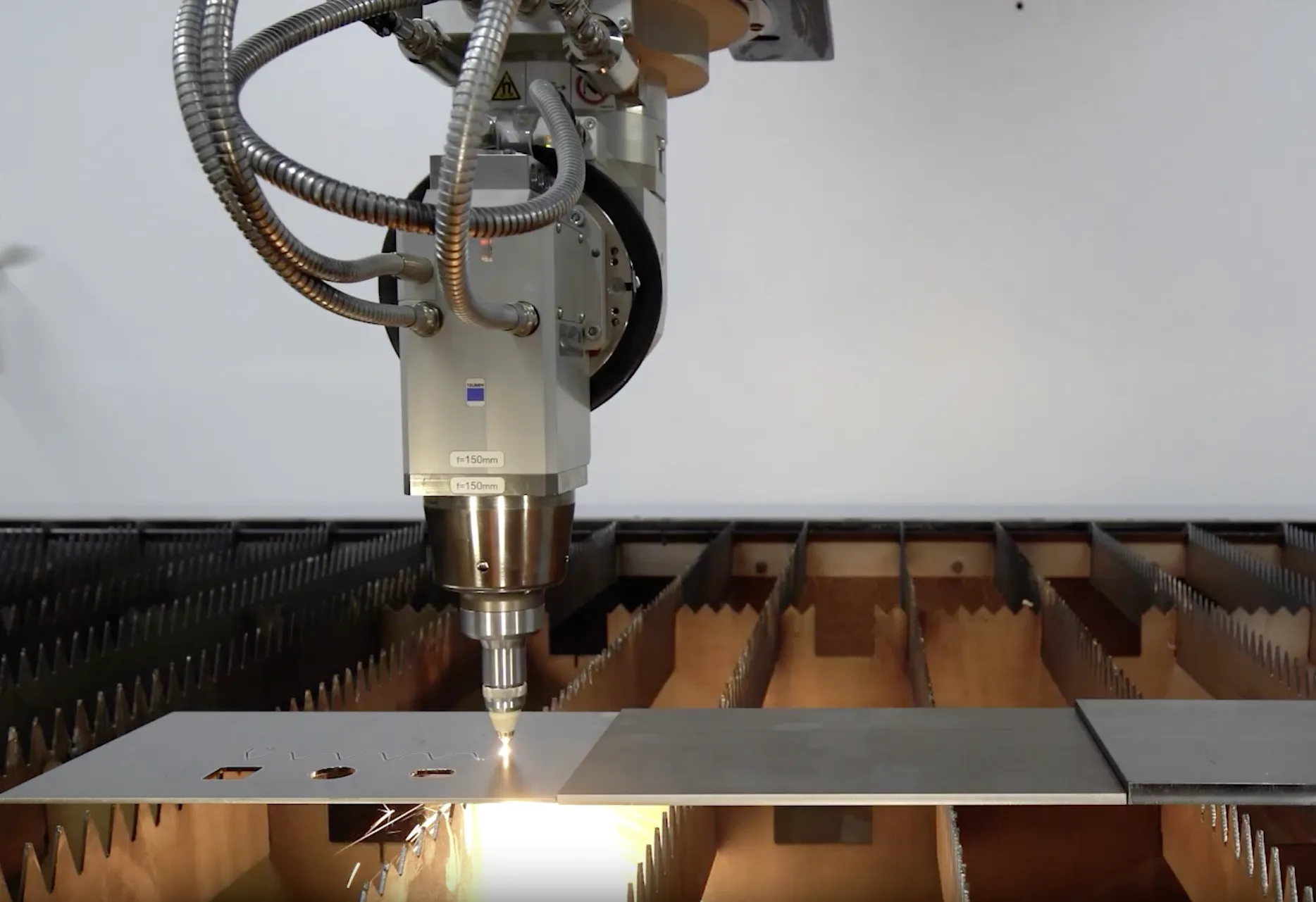

3D machining unlocks entirely new possibilities for geometries and design.

Precision and Cleanliness

Extremely precise cuts—ideal for fine contours and intricate patterns, with smooth cutting edges and minimal heat-affected zones.

Large Working Area

Accommodates workpieces up to 2,540 mm (X), 1,040 mm (Y), and 470 mm (Z).

Versatile Material Compatibility

From aluminum to the latest steel alloys—the TruLaser Cell 5030 handles them all with ease.

Anything is possible.

Well… almost.

With our new 3D laser, we can cut and weld angles between 15 and 95 degrees on request. Whether prototyping, custom one-off production, or small and large series—there’s virtually no special construction request we can’t fulfill.

So, what do you get instead? Almost limitless flexibility, maximum precision, and top-tier quality.

Images: TRUMPF SE + Co. KG | TRUMPF