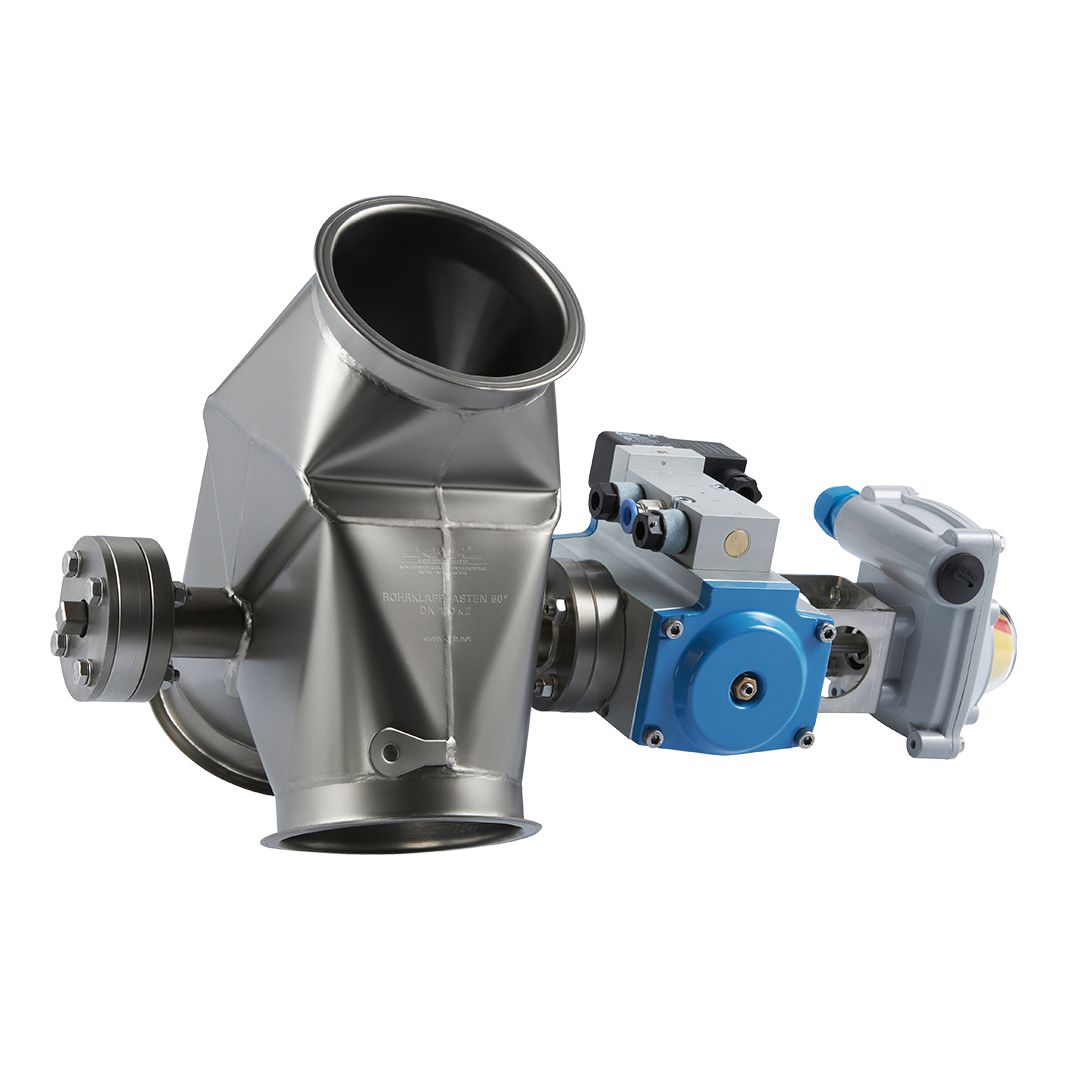

Special Designs – Pipes – Pipe Components – Distribution Systems

SMOOTH SOLUTION

KMH innovation: Blasted surfaces with a homogenous and attractive appearance.

Our perfectly smooth finish ensures less contamination and less abrasion. In addition, thanks to the KMH blasting process, there is no cracking corrosion. The improved surfaces are a real highlight, both technically and visually, and can even meet the high requirements of the food and pharmaceutical industries.⁽¹⁾

And it gets even better: You get the high quality of the blasted surfaces from us not only with short delivery times, but also at no additional cost when compared with our pickled components.

Since 1 November 2022, we have been delivering our products with blasted surfaces as standard!

The process developed by KMH is unique in the industry, because the blasting agent used consists of high-alloy stainless steel grains that do not contain any surface-damaging structures. The result is a particularly resistant and hygienic surface finish.

Of course, you can still get all stainless steel products in a pickled version if you wish.

THE ADVANTAGES OF BLASTED STAINLESS STEEL SURFACES

+ MAXIMUM ROUGHNESS Ra 0.8 μm⁽²⁾ possible

- Significant advantages in terms of hygiene: the smoother the surface, the fewer contaminants can adhere.

- The high requirements of the food and pharmaceutical industries for surfaces that come into contact with products can be met ⁽¹⁾

+ CORROSION RESISTANCE AND LOW WEAR

- No stress corrosion due to the minimally evasive impact during the blasting process.

- Hardly any micro-chipping, etching or scoring.

- Long-lasting products thanks to surface hardening.

+ MORE HYGIENE WITH LESS EFFORT

- Easy cleaning of the pipe systems thanks to the low adhesion of contaminants.

- Low downtimes – high system availability

+ SHORT DELIVERY TIMES

- Rapid availability: Execution of the blasting process in-house on special systems – independence from external service providers

+ IMPRESSIVE LOOK

- Particularly elegant look of your production systems.

- Technical hygiene is also visually conveyed at first glance.

OUR PLUS IN TERMS OF SUSTAINABILITY

- Short transport routes thanks to in-house blasting processes.

- The blasting agent is processed and returned to the circuit.

- The first provider in the market segment with certified energy and environmental management in accordance with DIN EN ISO 50001 and DIN EN ISO 14001.

⁽¹⁾ In the case of special requirements for surfaces, especially in the food and pharmaceutical sectors, comprehensive technical advice and coordination from our specialists is required. We will, of course, be pleased to advise you individually and personally on all products and areas of application. Please feel free to contact us: innovation@kmh.net

⁽²⁾ Measured using the stylus method/profile method. Blasted surfaces have a roughness depth of less than Ra 0.8µm. Depending on the length and diameter, the inner surfaces of the pipe remain unblasted, but they also have a roughness depth of less than Ra 0.8 μm. Weld seam areas and transitions, as well as small and add-on parts (e.g. levers, flanges, shafts), can have greater roughness depths on the inside and outside. The same applies to production-related processing traces. Our expert/competent team will be glad to advise you: innovation@kmh.net

Do you have any questions or need advice about our blasted surface?

Our expert sales and engineering team will be glad to advise you personally! If you wish, we will send you material samples of our blasted and pickled surfaces for direct comparison – just give us a call or email us!

Phone +49 4241 93900 · innovation@kmh.net · www.der-glatte-wahnsinn.de